The United States National Transportation Safety Board has issued a summary report on the rupture of the the Enbridge pipeline and subsequent oil spill at Marshall, Michigan, in 2010.

The report says that the probable cause of the oil spill included deficient integrity management at Enbridge, which allowed previously known crack defects in corroded areas to spread until the pipeline failed; inadequate training of control center personnel by Enbridge, which allowed the rupture to remain undetected for 17 hours and insufficient public awareness and education, which allowed the release to continue for nearly 14 hours after the first notification of an odor to local emergency response agencies.

The full NTSB report will be issued in the coming weeks.

Skeena Bulkley Valley Member of Parliament and NDP House Leader, Nathan Cullen, issued his own news release, saying, “Today’s report by the US National Transportation Safety Board (NTSB) into the deadly July 2010 Enbridge spill in Michigan identifies ‘a complete breakdown of safety at Enbridge’ and notes the company knowingly ‘failed to accurately assess the structural integrity of the pipeline.'”

“The findings are actually worse than we feared,” Cullen said. “They are a body blow of breathtaking proportions to Enbridge and yet another wake-up call to the Northwest of the dangers of allowing big oil to run a pipeline through our Northwest watersheds.”

Cullen commended NTSB chair Deborah Hersman for her frankness in terming Enbridge’s Michigan spill “”an accident that is a wake-up call to the industry, the regulator, and the public.”

Enbridge, Inc. Hazardous Liquid Pipeline Rupture

July 25, 2010

Marshall, MI

NATIONAL TRANSPORTATION SAFETY BOARD

Public Meeting of July 10, 2012

(Information subject to editing)

NTSB/PAR-12/01

This is a synopsis from the National Transportation Safety Board’s report and does not include the NTSB’s rationale for the conclusions, probable cause, and safety recommendations. Safety Board staff is currently making final revisions to the report from which the attached conclusions and safety recommendations have been extracted. The final report and pertinent safety recommendation letters will be distributed to recommendation recipients as soon as possible. The attached information is subject to further review and editing.

Executive Summary

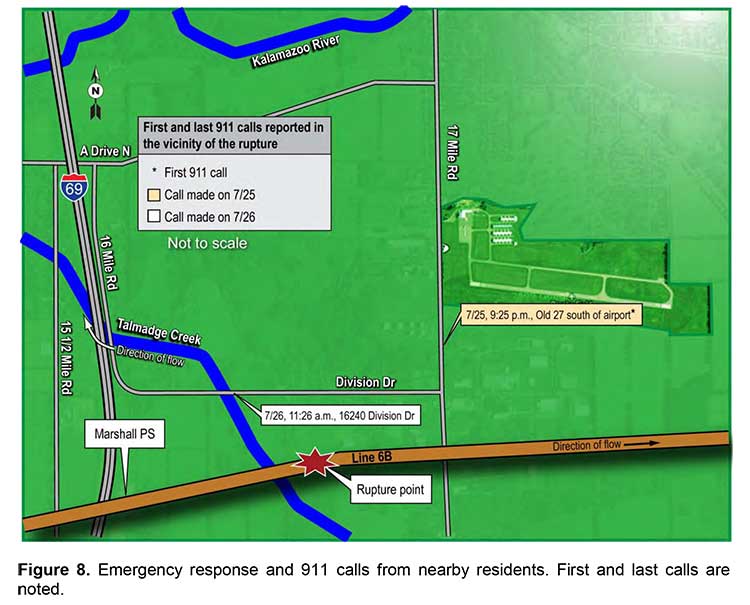

On Sunday, July 25, 2010, at 5:58 p.m., eastern daylight time, a segment of a 30-inch-diameter pipeline (Line 6B), owned and operated by Enbridge Incorporated (Enbridge) ruptured in a wetland in Marshall, Michigan. The rupture occurred during the last stages of a planned shutdown and was not discovered or addressed for over 17 hours. During the time lapse, Enbridge twice pumped additional oil (81 percent of the total release) into Line 6B during two startups; the total release was estimated to be 843,444 gallons of crude oil. The oil saturated the surrounding wetlands and flowed into the Talmadge Creek and the Kalamazoo River. Local residents self-evacuated from their houses, and the environment was negatively affected. Cleanup efforts continue as of the adoption date of this report, with continuing costs exceeding $767 million. About 320 people reported symptoms consistent with crude oil exposure. No fatalities were reported.

Conclusions

1. The following were not factors in this accident: cathodic protection, microbial corrosion, internal corrosion, transportation-induced metal fatigue, third-party damage, and pipe manufacturing defects.

2. Insufficient information was available from the postaccident alcohol testing; however, the postaccident drug testing showed that use of illegal drugs was not a factor in the accident.

3. Had the firefighters discovered the ruptured segment of Line 6B and called Enbridge, the two startups of the pipeline might not have occurred and the additional volume might not have been pumped.

4. The Line 6B segment ruptured under normal operating pressure due to corrosion fatigue cracks that grew and coalesced from multiple stress corrosion cracks, which had initiated in areas of external of corrosion beneath the disbonded polyethylene tape coating.

5. Title 49 Code of Federal Regulations 195.452(h) does not provide clear requirements regarding when to repair and when to remediate pipeline defects and inadequately defines the requirements for assessing the effect on pipeline integrity when either crack defects or cracks and corrosion are simultaneously present in the pipeline.

6. The Pipeline and Hazardous Materials Safety Administration (PHMSA) failed to pursue findings from previous inspections and did not require Enbridge Incorporated (Enbridge) to excavate pipe segments with injurious crack defects.

7. Enbridge’s delayed reporting of the “discovery of condition” by more than 460 days indicates that Enbridge’s interpretation of the current regulation delayed the repair of the pipeline.

8. Enbridge’s integrity management program was inadequate because it did not consider the following: a sufficient margin of safety, appropriate wall thickness, tool tolerances, use of a continuous reassessment approach to incorporate lessons learned, the effects of corrosion on crack depth sizing, and accelerated crack growth rates due to corrosion fatigue on corroded pipe with a failed coating.

9. To improve pipeline safety, a uniform and systematic approach in evaluating data for various types of in-line inspection tools is necessary to determine the effect of the interaction of various threats to a pipeline.

10. Pipeline operators should not wait until PHMSA promulgates revisions to 49 Code of Federal Regulations 195.452 before taking action to improve pipeline safety.

11. PII Pipeline Solutions’ analysis of the 2005 in-line inspection data for the Line 6B segment that ruptured mischaracterized crack defects, which resulted in Enbridge not evaluating them as crack-field defects.

12. The ineffective performance of control center staff led them to misinterpret the rupture as a column separation, which led them to attempt two subsequent startups of the line.

13. Enbridge failed to train control center staff in team performance, thereby inadequately preparing the control center staff to perform effectively as a team when effective team performance was most needed.

14. Enbridge failed to ensure that all control center staff had adequate knowledge, skills, and abilities to recognize and address pipeline leaks, and their limited exposure to meaningful leak recognition training diminished their ability to correctly identify the cause of the Material Balance System (MBS) alarms.

15. The Enbridge control center and MBS procedures for leak detection alarms and identification did not fully address the potential for leaks during shutdown and startup, and Enbridge management did not prohibit control center staff from using unapproved procedures.

16. Enbridge’s control center staff placed a greater emphasis on the MBS analyst’s flawed interpretation of the leak detection system’s alarms than it did on reliable indications of a leak, such as zero pressure, despite known limitations of the leak detection system.

17. Enbridge control center staff misinterpreted the absence of external notifications as evidence that Line 6B had not ruptured.

18. Although Enbridge had procedures that required a pipeline shutdown after 10 minutes of uncertain operational status, Enbridge control center staff had developed a culture that accepted not adhering to the procedures.

19. Enbridge’s review of its public awareness program was ineffective in identifying and correcting deficiencies.

20. Had Enbridge operated an effective public awareness program, local emergency response agencies would have been better prepared to respond to early indications of the rupture and may have been able to locate the crude oil and notify Enbridge before control center staff tried to start the line.

21. Although Enbridge quickly isolated the ruptured segment of Line 6B after receiving a telephone call about the release, Enbridge’s emergency response actions during the initial hours following the release were not sufficiently focused on source control and demonstrated a lack of awareness and training in the use of effective containment methods.

22. Had Enbridge implemented effective oil containment measures for fast-flowing waters, the amount of oil that reached Talmadge Creek and the Kalamazoo River could have been reduced.

23. PHMSA’s regulatory requirements for response capability planning do not ensure a high level of preparedness equivalent to the more stringent requirements of the U.S. Coast Guard and the U.S. Environmental Protection Agency.

24. Without specific Federal spill response preparedness standards, pipeline operators do not have response planning guidance for a worst-case discharge.

25. The Enbridge facility response plan did not identify and ensure sufficient resources were available for the response to the pipeline release in this accident.

26. If PHMSA had dedicated the resources necessary and conducted a thorough review of the Enbridge facility response plan, it would have disapproved the plan because it did not adequately provide for response to a worst-case discharge.

27. Enbridge’s failure to exercise effective oversight of pipeline integrity and control center operations, implement an effective public awareness program, and implement an adequate postaccident response were organizational failures that resulted in the accident and increased its severity.

28. Pipeline safety would be enhanced if pipeline companies implemented safety management systems.

Probable Cause

The National Transportation Safety Board (NTSB) determines that the probable cause of the pipeline rupture was corrosion fatigue cracks that grew and coalesced from crack and corrosion defects under disbonded polyethylene tape coating, producing a substantial crude oil release that went undetected by the control center for over 17 hours. The rupture and prolonged release were made possible by pervasive organizational failures at Enbridge Incorporated (Enbridge) that included the following:

- Deficient integrity management procedures, which allowed well-documented crack defects in corroded areas to propagate until the pipeline failed.

- Inadequate training of control center personnel, which allowed the rupture to remain undetected for 17 hours and through two startups of the pipeline.

- Insufficient public awareness and education, which allowed the release to continue for nearly 14 hours after the first notification of an odor to local emergency response agencies.

Contributing to the accident was the Pipeline and Hazardous Materials Safety Administration’s (PHMSA) weak regulation for assessing and repairing crack indications, as well as PHMSA’s ineffective oversight of pipeline integrity management programs, control center procedures, and public awareness.

Contributing to the severity of the environmental consequences were (1) Enbridge’s failure to identify and ensure the availability of well-trained emergency responders with sufficient response resources, (2) PHMSA’s lack of regulatory guidance for pipeline facility response planning, and (3) PHMSA’s limited oversight of pipeline emergency preparedness that led to the approval of a deficient facility response plan.

Recommendations

To the U.S. Secretary of Transportation:

1. Audit the Pipeline and Hazardous Materials Safety Administration’s onshore pipeline facility response plan program’s business practices, including reviews of response plans and drill programs, and take appropriate action to correct deficiencies.

2. Allocate sufficient resources as necessary to ensure that the Pipeline and Hazardous Materials Safety Administration’s onshore pipeline facility response plan program meets all of the requirements of the Oil Pollution Act of 1990.

To the Pipeline and Hazardous Materials Safety Administration:

3. Revise Title 49 Code of Federal Regulations 195.452 to clearly state (1) when an engineering assessment of crack defects, including environmentally assisted cracks, must be performed; (2) the acceptable methods for performing these engineering assessments, including the assessment of cracks coinciding with corrosion with a safety factor that considers the uncertainties associated with sizing of crack defects; (3) criteria for determining when a probable crack defect in a pipeline segment must be excavated and time limits for completing those excavations; (4) pressure restriction limits for crack defects that are not excavated by the required date; and (5) acceptable methods for determining crack growth for any cracks allowed to remain in the pipe, including growth caused by fatigue, corrosion fatigue, or stress corrosion cracking as applicable.

4. Revise Title 49 Code of Federal Regulations 195.452(h)(2), the “discovery of condition,” to require, in cases where a determination about pipeline threats has not been obtained within 180 days following the date of inspection, that pipeline operators notify the Pipeline and Hazardous Materials Safety Administration and provide an expected date when adequate information will become available.

5. Conduct a comprehensive inspection of Enbridge Incorporated’s integrity management program after it is revised in accordance with Safety Recommendation (11).

6. Issue an advisory to all hazardous liquid and natural gas pipeline operators describing the circumstances of the accident in Marshall, Michigan—including the deficiencies observed in Enbridge Incorporated’s integrity management program—and ask them to take appropriate action to eliminate similar deficiencies.

7. Develop requirements for team training of control center staff involved in pipeline operations similar to those used in other transportation modes.

8. Extend operator qualification requirements in Title 49 Code of Federal Regulations 195 Subpart G to all hazardous liquid and gas transmission control center staff involved in pipeline operational decisions.

9. Amend Title 49 Code of Federal Regulations Part 194 to harmonize onshore oil pipeline response planning requirements with those of the U.S. Coast Guard and the U.S. Environmental Protection Agency for facilities that handle and transport oil and petroleum products to ensure that pipeline operators have adequate resources available to respond to worst-case discharges.

10. Issue an advisory bulletin to notify pipeline operators (1) of the circumstances of the Marshall, Michigan, pipeline accident, and (2) of the need to identify deficiencies in facility response plans and to update these plans as necessary to conform with the nonmandatory guidance for determining and evaluating required response resources as provided in Appendix A of Title 49 Code of Federal Regulations 194, “Guidelines for the Preparation of Response Plans.”

To Enbridge Incorporated:

11. Revise your integrity management program to ensure the integrity of your hazardous liquid pipelines as follows: (1) implement, as part of the excavation selection process, a safety margin that conservatively takes into account the uncertainties associated with the sizing of crack defects from in-line inspections; (2) implement procedures that apply a continuous reassessment approach to immediately incorporate any new relevant information as it becomes available and reevaluate the integrity of all pipelines within the program; (3) develop and implement a methodology that includes local corrosion wall loss in addition to the crack depth when performing engineering assessments of crack defects coincident with areas of corrosion; and (4) develop and implement a corrosion fatigue model for pipelines under cyclic loading that estimates growth rates for cracks that coincide with areas of corrosion when determining reinspection intervals.

12. Establish a program to train control center staff as teams, semiannually, in the recognition of and response to emergency and unexpected conditions that includes supervisory control and data acquisition system indications and Material Balance System software.

13. Incorporate changes to your leak detection processes to ensure that accurate leak detection coverage is maintained during transient operations, including pipeline shutdown, pipeline startup, and column separation.

14. Provide additional training to first responders to ensure that they (1) are aware of the best response practices and the potential consequences of oil releases and (2) receive practical training in the use of appropriate oil-containment and -recovery methods for all potential environmental conditions in the response zones.

15. Review and update your oil pipeline emergency response procedures and equipment resources to ensure that appropriate containment equipment and methods are available to respond to all environments and at all locations along the pipeline to minimize the spread of oil from a pipeline rupture.

16. Update your facility response plan to identify adequate resources to respond to and mitigate a worst-case discharge for all weather conditions and for all your pipeline locations before the required resubmittal in 2015.

To the American Petroleum Institute:

17. Facilitate the development of a safety management system standard specific to the pipeline industry that is similar in scope to your Recommended Practice 750, Management of Process Hazards. The development should follow established American National Standards Institute requirements for standard development.

To the Pipeline Research Council International, Inc.:

18. Conduct a review of various in-line inspection tools and technologies—including, but not limited to: tool tolerance, the probability of detection, and the probability of identification—and provide a model with detailed step-by-step procedures to pipeline operators for evaluating the effect of interacting corrosion and crack threats on the integrity of pipelines.

To the International Association of Fire Chiefs and the National Emergency Number Association:

19. Inform your members about the circumstances of the Marshall, Michigan, pipeline accident and urge your members to aggressively and diligently gather from pipeline operators system-specific information about the pipeline systems in their communities and jurisdictions.

Previous Recommendation Reiterated in this Report

To the Pipeline and Hazardous Materials Safety Administration:

Require operators of natural gas transmission and distribution pipelines and hazardous liquid pipelines to provide system-specific information about their pipeline systems to the emergency response agencies of the communities and jurisdictions in which those pipelines are located. This information should include pipe diameter, operating pressure, product transported, and potential impact radius. (P-11-8)

A live and archived webcast of the proceedings will be available at http://www.capitolconnection.net/capcon/ntsb/ntsb.htm. To report any difficulties viewing the webcast, please call 703-993-3100 and ask for webcast technical support.

The complete report will appear on ntsb.gov in several weeks.

Enbridge says it has e worked closely and cooperatively with the NTSB throughout its investigation. The company isnow reviewing the summary report and will not comment specifically on the contents of the Final Report until it is released by the NTSB Board and analysis of the report has been completed.

The NTSB says the tug was on autopilot when the second mate fall sleep on watch and it missed course correction near Ivory Island. The tug had a computerized electronic chart system (ECS) on board that should have sounded an alarm when the way point for the course correction was missed, but the mate told the NTSB, the tug was not using that navigation tool on the night of the accident. According to the second mate, it was

The NTSB says the tug was on autopilot when the second mate fall sleep on watch and it missed course correction near Ivory Island. The tug had a computerized electronic chart system (ECS) on board that should have sounded an alarm when the way point for the course correction was missed, but the mate told the NTSB, the tug was not using that navigation tool on the night of the accident. According to the second mate, it was